For a production manager, these costs are vital for identifying areas of waste and potential improvements in the manufacturing cycle. Meanwhile, investors and analysts view conversion costs as an indicator of a company’s operational health and profitability. Overhead costs, also known as indirect costs, are incurred by a business to maintain its operations but cannot be directly attributed to a specific product or service. These costs are essential for the smooth functioning of the organization and include expenses such as rent, utilities, salaries of administrative staff, and office supplies. While direct costs vary with production levels, overhead costs remain relatively stable regardless of output.

Understanding Cost Behavior: Fixed vs. Variable

Please keep in mind that depreciation charges, insurance expenses, cost expenses, and electricity expenses are all considered manufacturing overhead. Indirect materials, electricity charges and salaries of engineer and supervisor are all indirect costs and have, therefore, been added together to obtain total manufacturing overhead cost. During a month, Company B has a total cost of $55,000 in direct labor and $66,000 in factory overhead costs. Thus, conversion costs are all manufacturing costs except for the cost of raw materials. Like prime costs, conversion costs are used to gauge the efficiency of a production process, but conversion cost also takes into account overhead expenses that are left out of prime cost calculations.

Importance of Conversion Costs

The conversion cost affects both the COGS and the inventory valuation, depending on the method used to calculate it. The weighted average method assigns the same conversion cost per unit to both the COGS and the inventory valuation. The FIFO method assigns a lower conversion cost per unit to the COGS and a higher conversion cost per unit to the inventory valuation. The standard cost method assigns the standard conversion cost per unit to both the COGS and the inventory valuation, and reports the variance as a separate item in the income statement or the balance sheet.

Definition of Conversion Costs

In summary, managing and reducing conversion costs requires a holistic approach, combining process optimization, strategic partnerships, employee engagement, and technological advancements. By implementing these strategies, businesses can achieve sustainable growth and maintain a competitive edge in today’s dynamic market. The table below highlights the key differences between conversion costs and prime costs.

For instance, the factory’s monthly electricity bill is an overhead cost that must be spread across all the products made during that month. The key difference between prime and conversion costs is the calculation of both the costs. The conversion costs prime cost of a product is calculated by adding all of its direct expenses together. This includes direct material costs of a product which are ignored when calculating the conversion cost of the product. Similarly, when calculating the conversion cost of a product, the production or factory overheads of the product are considered. These production overheads are ignored when calculating the prime cost of the product.

What Is Conversion Cost? Formula, Example, and Application

Conversion cost is a useful tool for cost accounting and management, and it can help to improve the performance and profitability of any business. Conversion Cost includes direct labor and manufacturing overhead, covering all production expenses. Prime Cost, however, is the sum of direct materials and direct labor, focusing specifically on fundamental production costs. Conversion Cost is the total money a company spends to transform raw materials into finished products. It includes direct labor (workers’ pay) and manufacturing overhead (other production expenses). Manufacturing overhead (MOH) is the second and often most complex component of the conversion cost calculation.

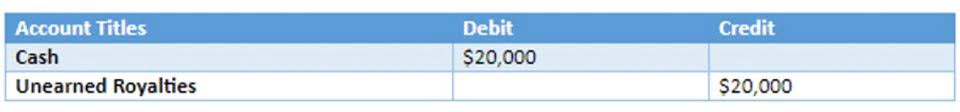

For example, in the production of a watch, direct materials are all costs related to materials that go directly into the watch such as the components that go inside the watch, the exterior frame or the straps. Direct labor includes costs such as salaries or wages of the employees that are involved in the production process. The direct expenses are expenses that are directly related to the production of the watch, such as any royalties paid for the production assets = liabilities + equity of the watch. Conversion costs include indirect materials, indirect labor, and other overhead costs.

- Direct labor, as mentioned above, refers to the salaries of production workers.

- For instance, if a company spends an additional $1 million on labor and overhead to produce a batch of goods, this cost must be recouped through the sale price, affecting the final price consumers pay.

- Simultaneously, automation often leads to higher overhead costs, including depreciation of equipment, maintenance, and electricity.

- Some common examples are insurance, building maintenance, machine breakup, and taxes on equipment or machining.

- Examples abound, from automotive manufacturers streamlining assembly lines to reduce labor hours, to software companies automating code testing to minimize error-related delays.

Identify the direct labor and manufacturing overhead costs for a given period. Direct labor costs are the wages and benefits paid to the workers who directly work on the product. Manufacturing overhead costs are the indirect costs that support the production process, such as utilities, rent, depreciation, maintenance, etc. Calculating Conversion Cost involves adding up the direct labor costs and manufacturing overhead costs.

1 Automating Production Processes

For example, let’s consider a company that manufactures electronic components. The conversion cost for a particular component is calculated to be $5 per unit, which includes $3 for direct labor and $2 for manufacturing overhead. However, the company must also consider the potential for increased lead times, the risk of supply chain disruptions, and the loss Remote Bookkeeping of control over the manufacturing process. If the company has a strategic focus on innovation and quality, maintaining in-house production might be the preferred choice, despite the higher per-unit cost. Overhead costs are the indirect costs that are not directly traceable to a specific product or process, such as rent, utilities, depreciation, and insurance. They can be either variable or fixed, depending on whether they change with the level of production or not.